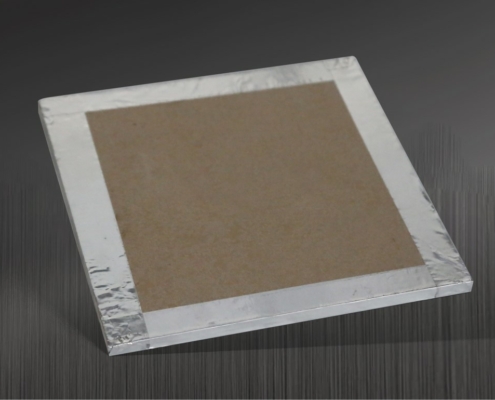

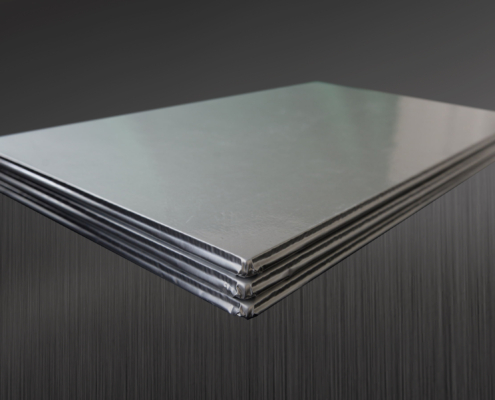

The unicorn product spectrum offers a broad range of microporous insulation products. Each product is suitable for different application and deployment scenarios. The product spectrum comprises two product families, the silica core materials for vacuum insulation panels (VIPs) and the high temperature microporous insulation panels for industrial applications.

Let the Unicorn team know your insulation task - write us!

Other products are about to come. Let the Unicorn team know your insulation task so we can discuss solutions for you.